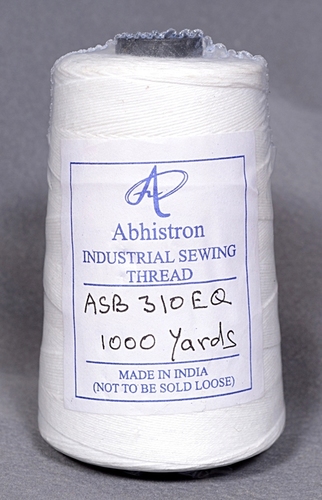

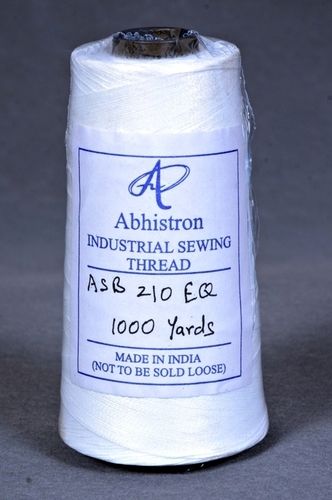

Polypropylene Thread

Polypropylene Thread Specification

- Length

- 500m, 1000m, per spool (or as required)

- Luster

- Semi-Dull to Bright

- Twist direction

- S or Z twist as specified

- Material

- Polypropylene

- Character

- High Strength

- Properties

- Lightweight, Chemical Resistant, Non-Absorbent

- Style

- Twisted

- Usage

- Industrial sewing, Bag stitching, Carpet overlocking, Packaging

- Technique

- Machine Spun

- Yarn Type

- Filament

- Pattern

- Dyed

- Attributes

- UV Resistant, Mildew Proof

- Weight

- As required (customized options available)

- Yarn Count

- 210 Denier and above

- Color

- White, Multiple Colors Available

Polypropylene Thread Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 100 Kilograms Per Week

- Delivery Time

- 5 Days

About Polypropylene Thread

A Polypropylene Thread is a high bulk, naturally antistatic thread that is well-suited for outdoor and automotive use. Use it for sewing textiles, landscape fabrics, sand bags, gravel bags, silt fences, ground covers, automobile trim, carpets, blankets, wall coverings, upholstery, industrial fabrics, and clothing. The main benefit of polypropylene as a fabric is its moisture transfer abilities; this textile cannot absorb any moisture. It is perhaps the strongest type of thread, which can be used for Bag Stitching purposes. The offered high end Polypropylene Thread is made available for use in a number of industries.

Technical Specification

|

Size/Length |

ADJUSTABLE |

|

Usage/Application |

Sewing |

|

Brand |

ABHISTRON |

|

Packaging Type |

Reel |

|

Packaging Size |

As per customer requirement |

|

Pattern |

Plain |

Versatility for Industrial Applications

Polypropylene threads high strength, chemical resistance, and minimal moisture absorption make it ideal for demanding industrial uses. Whether for stitching heavy bags, reinforcing carpets, or packaging products, its durability and smooth finish ensure secure and neat seams. Available in various weights and colors, this thread can be tailored for specific needs, meeting rigorous standards in textile and manufacturing sectors.

Customizable to Meet Your Requirements

Choose the polypropylene thread that best fits your project, with options for color, tex, length, packing, and twist direction (S or Z). Producers, exporters, and distributors in India offer solutions designed for unique applications, ensuring both functionality and aesthetic appeal. Clients can specify luster, yarn count, and delivery formspool, cone, or hankallowing seamless integration into established workflows.

Outstanding Environmental Resistance

This thread is engineered to withstand exposure to acids, alkalis, and organic solvents, while also resisting rot, mildew, and UV degradation. Its robust construction ensures durability in harsh environments, making it reliable for outdoor or high-wear contexts. With negligible moisture absorption and minimal shrinkage, polypropylene thread maintains its integrity over time, ensuring high performance.

FAQs of Polypropylene Thread:

Q: How does polypropylene thread benefit industrial sewing and heavy-duty applications?

A: Polypropylene thread offers excellent tensile strength and high resistance to chemicals, UV rays, and mildew, making it suitable for demanding tasks such as industrial sewing, bag stitching, carpet overlocking, and packaging. Its durability ensures secure seams that withstand tough usage and environmental exposure.Q: What are the available packaging options for polypropylene thread?

A: Polypropylene thread is supplied in cones, spools, or hanks, allowing flexibility for diverse manufacturing and industrial workflows. Custom packing options are available to meet specific client requirements, ensuring convenient storage and usage.Q: When should I choose polypropylene thread over other types?

A: Consider polypropylene thread when you need a lightweight, high-strength, chemical-resistant, and non-absorbent thread for applications exposed to harsh or wet environments. It is ideal for outdoor, heavy-duty, and industrial uses where durability and resistance to rot or moisture are essential.Q: Where is polypropylene thread commonly used in industry?

A: This thread is widely utilized in industries such as textile manufacturing, packaging, carpet production, bag making, and upholstery. It is especially chosen for environments that require sturdy, rot-proof, and minimally shrinking thread options.Q: What customization options are offered for polypropylene thread?

A: Clients can specify color, tex (thickness), yarn count, twist direction (S or Z), packing style, luster, and spool length. Suppliers in India accommodate custom requests to ensure that the thread meets the exact requirements for each application.Q: What is the process for producing polypropylene thread?

A: Polypropylene thread is typically machine spun from filament yarn, often twisted for added strength and durability. It is then dyed as needed, wound onto spools, cones, or hanks, and packed according to client specifications.Q: How does the threads environmental resistance offer long-term benefits?

A: Its good resistance to acids, alkalis, organic solvents, UV rays, and mildew prevents degradation over time, even in challenging environments. This ensures a longer lifespan for sewn products and reduces maintenance or replacement costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Bag Closing Thread Category

Bag Closing Spun Polyester Thread

Price 160.0 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 2 to 5 kg Kilograms (kg)

Character : Other

Pattern : Other

Style : Other

Bag Closing Thread Polyester

Price 40 INR / Piece

Minimum Order Quantity : 200 Boxes

Weight : 200Gram To 3Kg Grams (g)

Character : Spun

Pattern : Other

Style : Other

PP Bag Closing Thread

Price 40 INR / Piece

Minimum Order Quantity : 200 Boxes

Weight : 150 Gram To 5 kg Grams (g)

Character : Twisted

Pattern : Other

Style : Other

Portable Closer Machine Thread

Price 165 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Weight : 1.25 to 3 kg Kilograms (kg)

Character : Other

Pattern : Other

Style : Other

Send Inquiry

Send Inquiry Send SMS

Send SMS